Fiberglass

Fiberglass

The Unique Molecular properties of Fiberglass Make it the Ideal Structural Material for Repairing:

Pool Cracks

Commercial Pools

All Types of Pool Shells

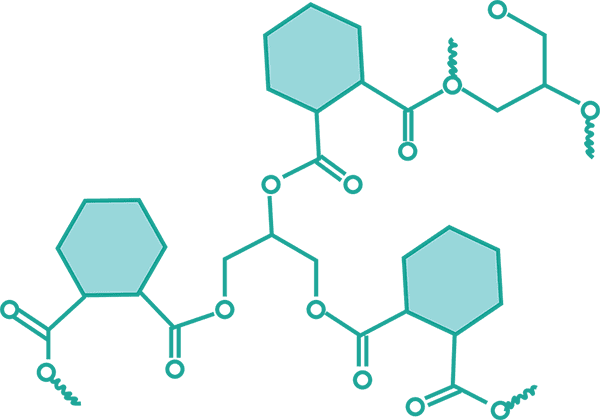

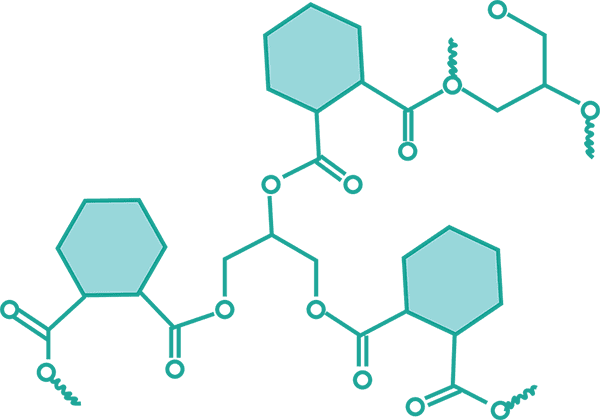

What is Fiberglass?

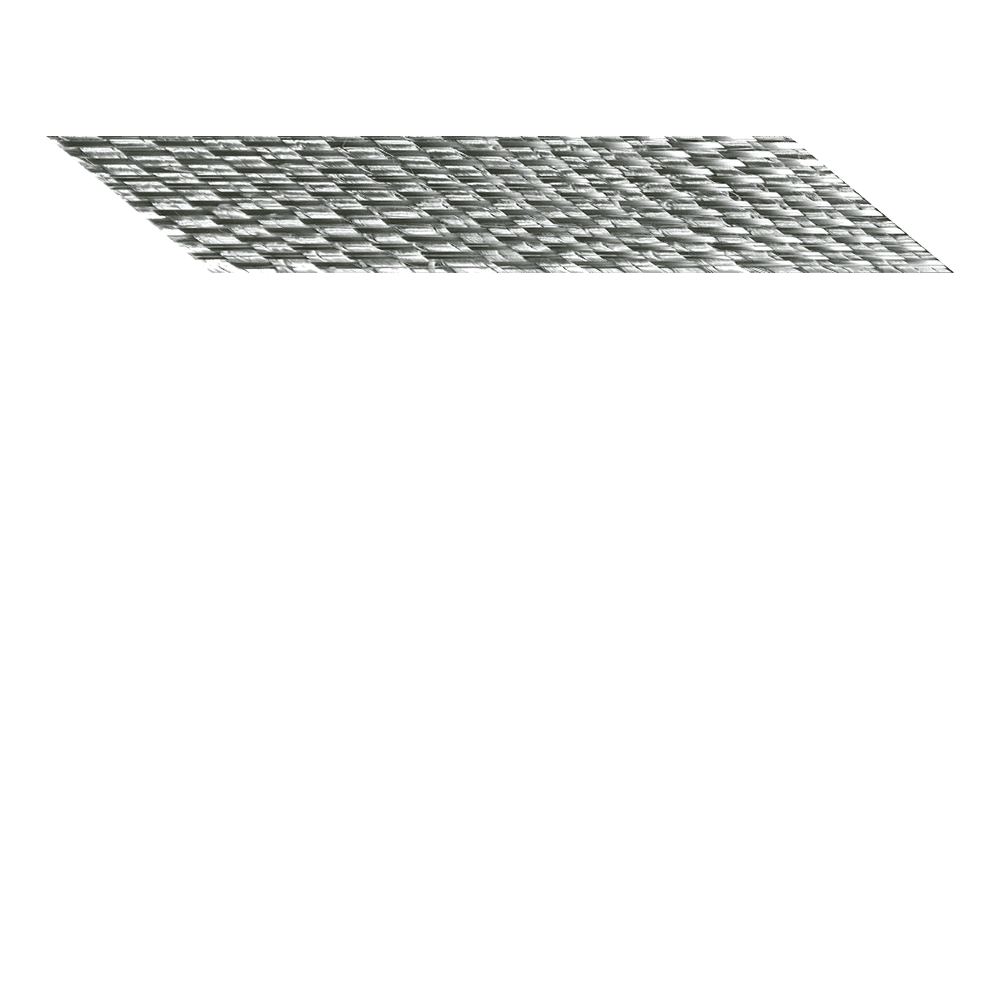

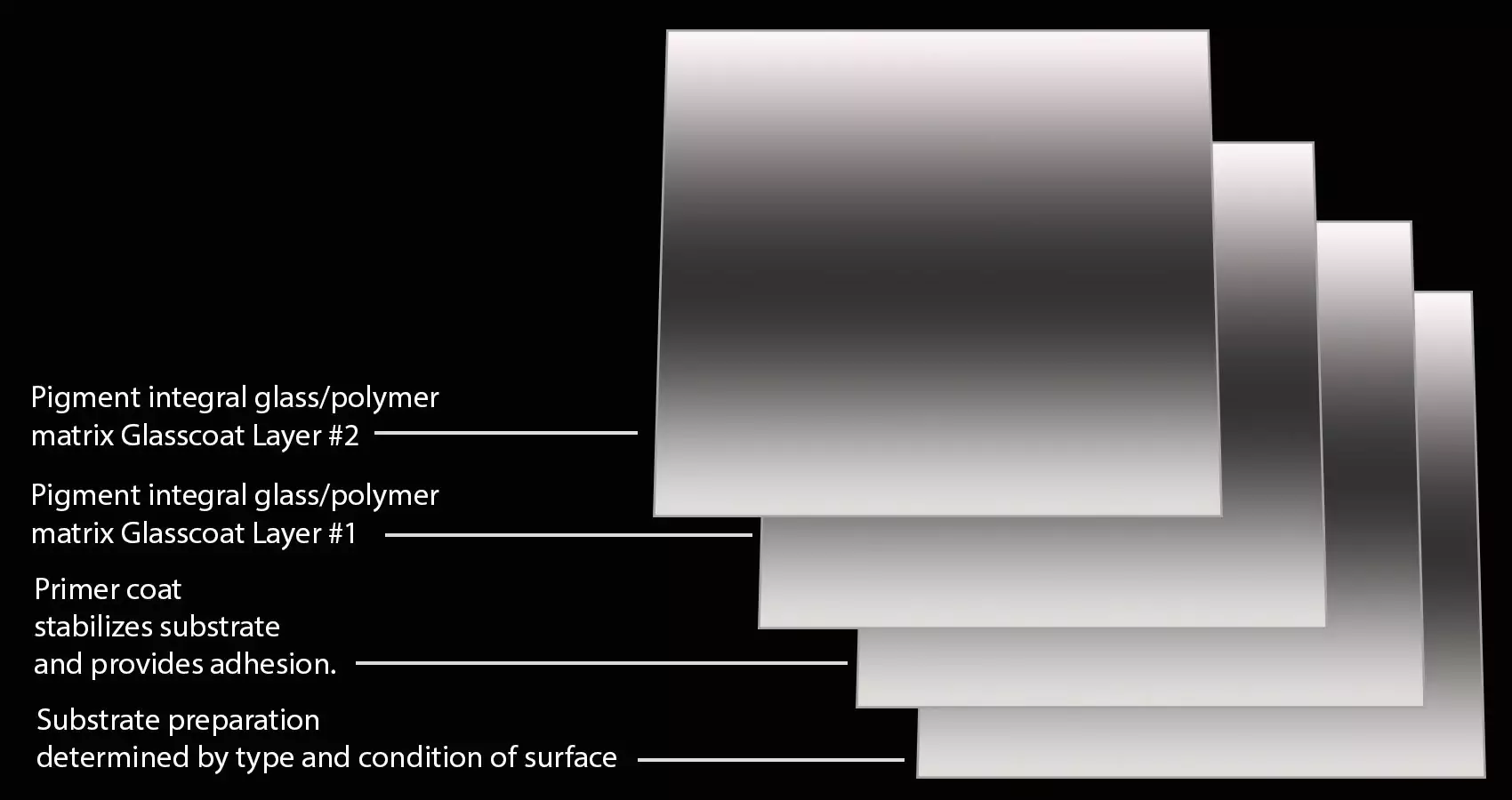

5 Layers of Strength

Gel Coat———————

Vinyl Ester Resin———————

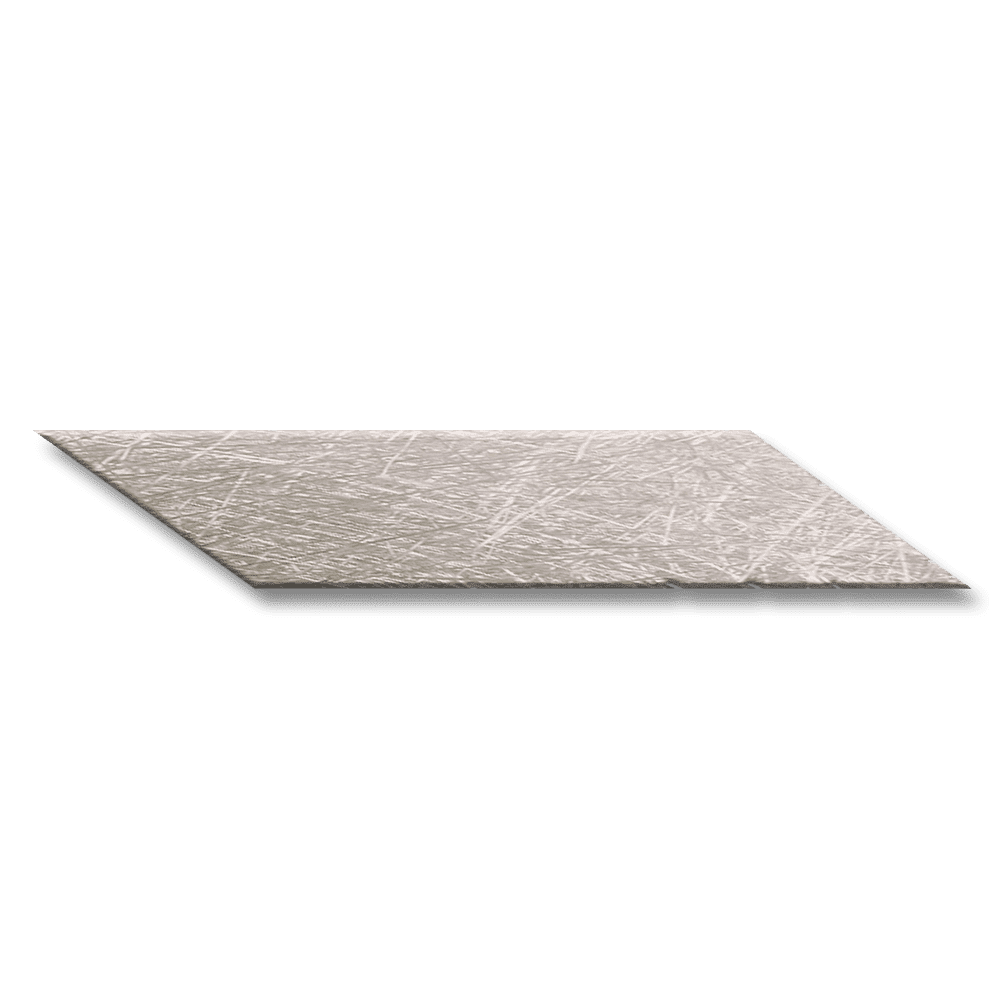

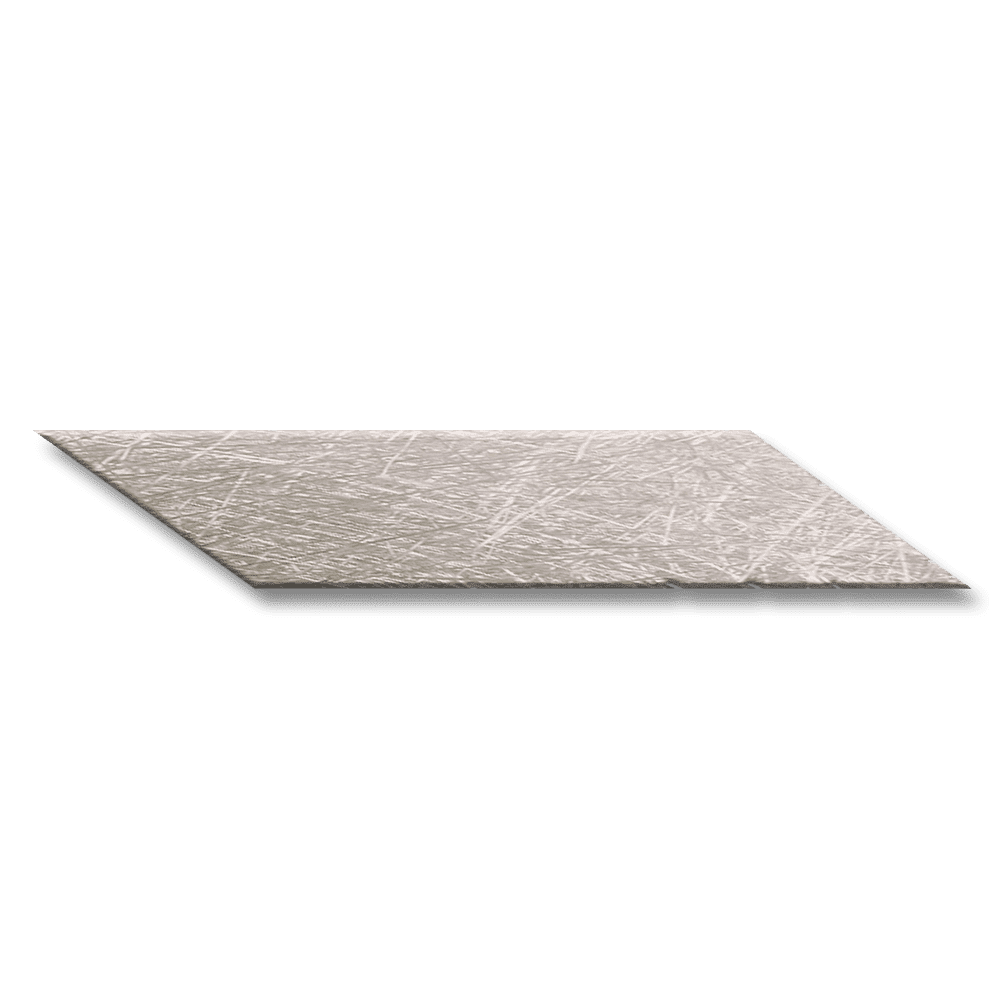

Woven Roving———————

2 Layers Chopped Fiberglass———————

2 Layers Chopped Fiberglass

Woven Roving

Vinyl Ester Resin Plus Gel Coat

Fiberglass material being installed to the interior surface of a swimming pool has Modernized the swimming pool resurfacing industry

Which Interior Resurface Material Type Is Right For Your Swimming Pool or Spa?

Plaster

A Natural Porous Finish

4,500 PSI

Composite

As smooth as an egg shell. Stronger & More Durable Compared To Plaster & Mini Pebble.

18,000 PSI

Pebble

We install all types of aggregate and pebble finishes.

8,500 PSI

We install all types of resurfacing materials; plaster, pebble, fiberglass. We do not push our customers to go with one option or the other.

Here are the facts that make each resurface material different:

Composite vs. Plaster

Composite

Plaster

Stains

Fiberglass offers resistance to stains with its easy-to-clean surface.

Little resistance to stains and blemishes even if the surface has been recently applied.

Stains

Composite: Fiberglass offers resistance to stains with its easy-to-clean surface.

Plaster: Little resistance to stains and blemishes even if the surface has been recently applied.

Algae Resistance

The smooth, dense, non-porous surface of fiberglass prevents algae from adhering.

Algae adheres to porous surfaces.

Algae Resistance

Composite: The smooth, dense, non-porous surface of fiberglass prevents algae from adhering.

Plaster: Algae adheres to porous surfaces.

Chemical Demand

Noticeable reduction in chemical usage due to the inert nature of fiberglass. Makes pool chemicals more efficient.

Plaster and Pebble Tec require a high demand for chemicals at all times. It is a reactive surface.

Chemical Demand

Composite: Noticeable reduction in chemical usage due to the inert nature of fiberglass. Makes pool chemicals more efficient.

Plaster: Plaster and Pebble Tec require a high demand for chemicals at all times. It is a reactive surface.

Attractiveness

Fiberglass maintains its attractive appearance.

Becomes unsightly when stained or deteriorated.

Attractiveness

Composite: Fiberglass maintains its attractive appearance.

Plaster: Becomes unsightly when stained or deteriorated.

Durability

The superior corrosion-resistant and inert properties of fiberglass ensure exceptional durability.

Depends on application. Re-plastering often separates from the original surface due to poor adhesion. Material limitations reduce the durability of plaster and Pebble Tec.

Durability

Composite: The superior corrosion-resistant and inert properties of fiberglass ensure exceptional durability.

Plaster: Depends on application. Re-plastering often separates from the original surface due to poor adhesion. Material limitations reduce the durability of plaster and Pebble Tec.

Water Chemistry

The inert surface of fiberglass is less sensitive to out-of-balance water chemistry.

Very sensitive to incorrect water chemistry. Plaster surface is easily compromised.

Water Chemistry

Composite: The inert surface of fiberglass is less sensitive to out-of-balance water chemistry.

Plaster: Very sensitive to incorrect water chemistry. Plaster surface is easily compromised.

Life Expectancy

Exceeds that of Plaster and Pebble Tec. Time tested with 25 years industry experience.

Varies. Depends on water chemistry, maintenance regime, plaster mix, and application technique.

Life Expectancy

Composite: Exceeds that of Plaster and Pebble Tec. Time tested with 25 years industry experience.

Plaster: Varies. Depends on water chemistry, maintenance regime, plaster mix, and application technique.

Leachable

Materials

Due to the inert nature of fiberglass, no leachable material is available to cause roughness. The surface remains smooth.

Salts / Plaster constituents will adhere and create a very abrasive surface.

Leachable

Materials

Composite: Due to the inert nature of fiberglass, no leachable material is available to cause roughness. The surface remains smooth.

Plaster: Salts / Plaster constituents will adhere and create a very abrasive surface.

Startup

Simple. No brushing needed. Allow the fiberglass to cure and then start up.

Plaster and Pebble Tec requires brushing and attention.

Compare Surface Materials

Fiberglass is reinforced and better than plaster (higher strength and durability)

Composite is a cleaner installation although it requires more skill to handle

Plaster requires a truck with a long hoses and other pieces of equipment

Composite and mini pebble are easiest to maintain

Advantages of Plaster |

Disadvantages of Plaster |

|---|---|

Classic appearance |

Prone to cracking and etching |

Initial cost is lower |

Requires more frequent resurfacing |

Smooth texture |

May require more chemicals to maintain |

Advantages of Mini Pebble |

Disadvantages of Mini Pebble |

|---|---|

Natural, textured appearance |

Can be rough on the skin |

Improved durability compared to plaster |

More expensive than plaster |

Resists stains and etching |

May require more maintenance |

Advantages of Composite (Over Plaster and Mini Pebble) |

Disadvantages of Composite |

|---|---|

Exceptional durability and longevity |

Higher initial cost |

Low maintenance and fewer chemicals |

May have limited color options |

Smooth and comfortable surface |

Requires professional installation |

Resists cracking, staining, and etching |

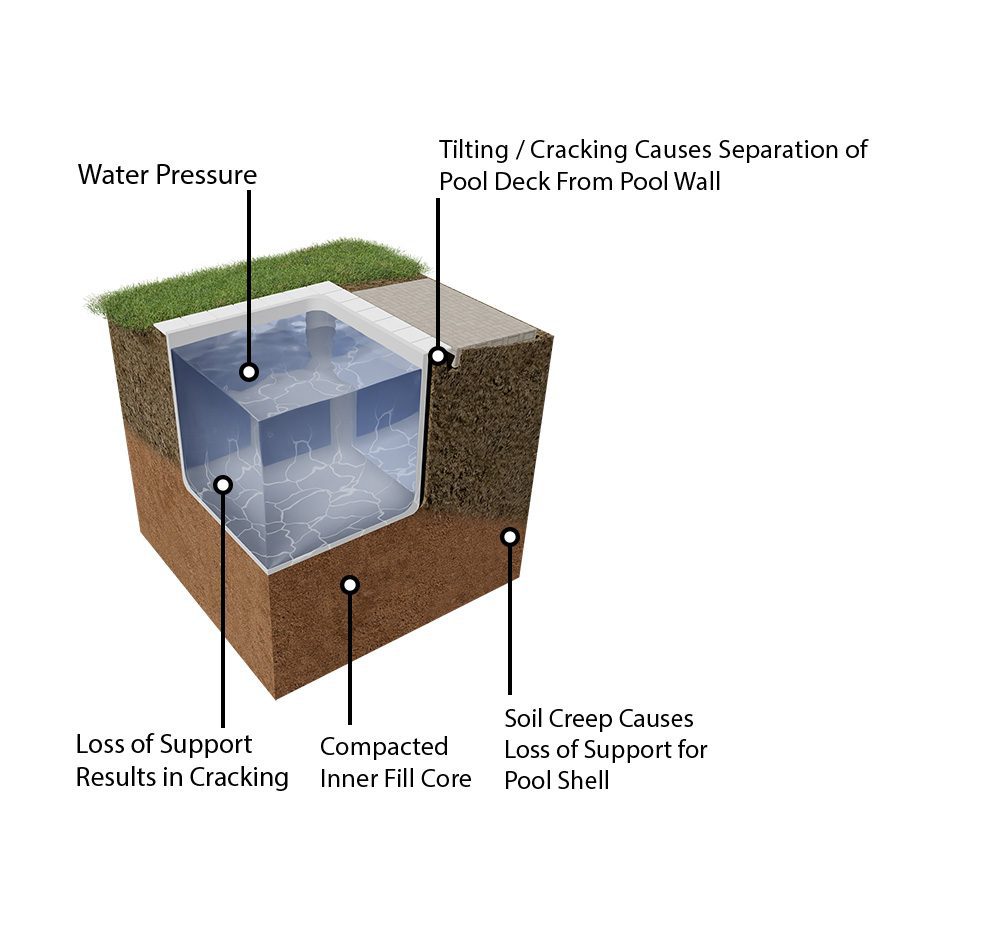

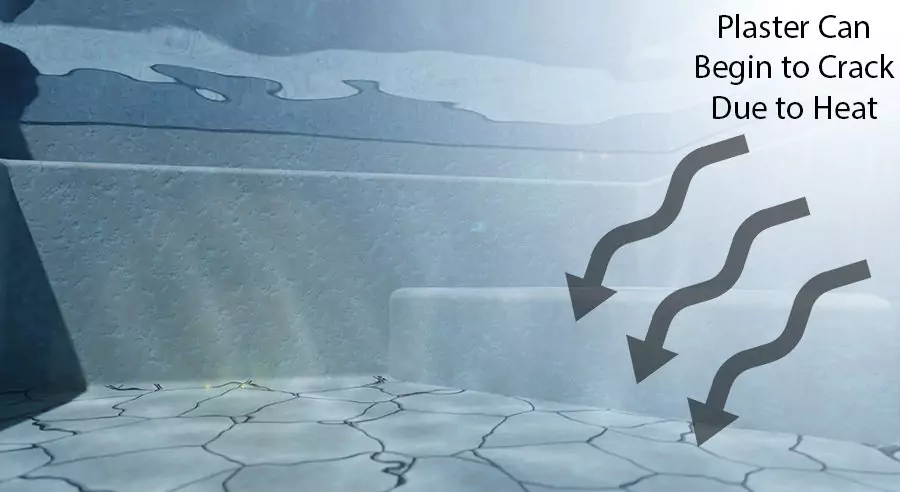

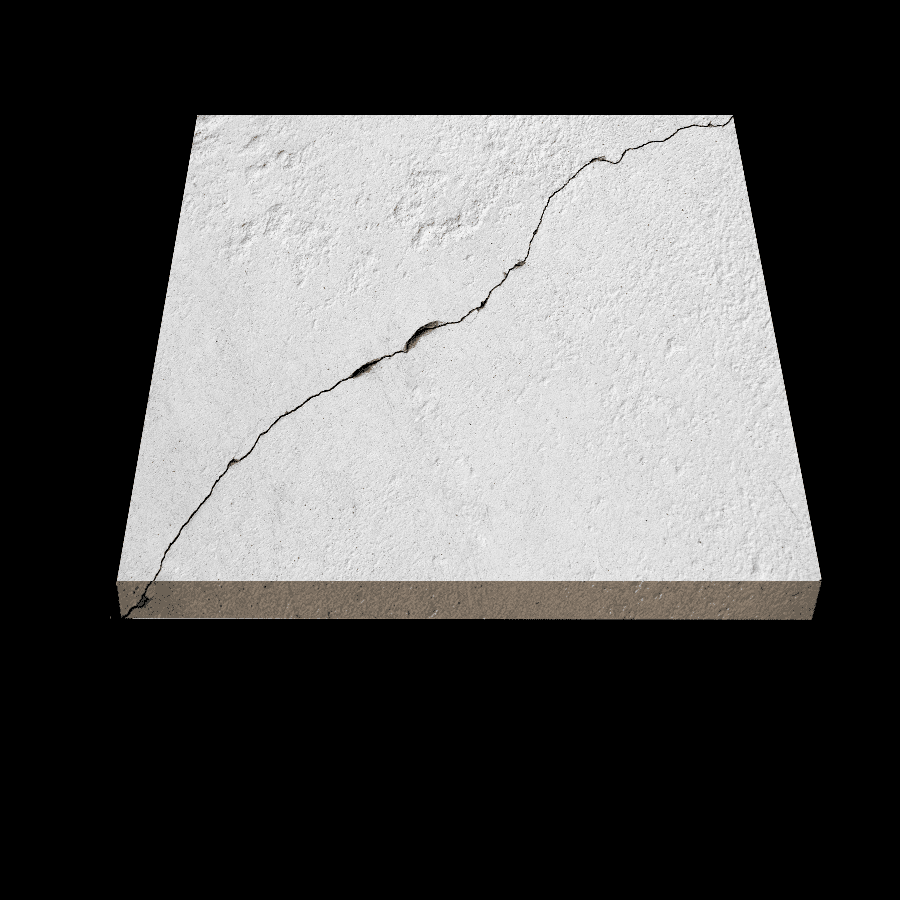

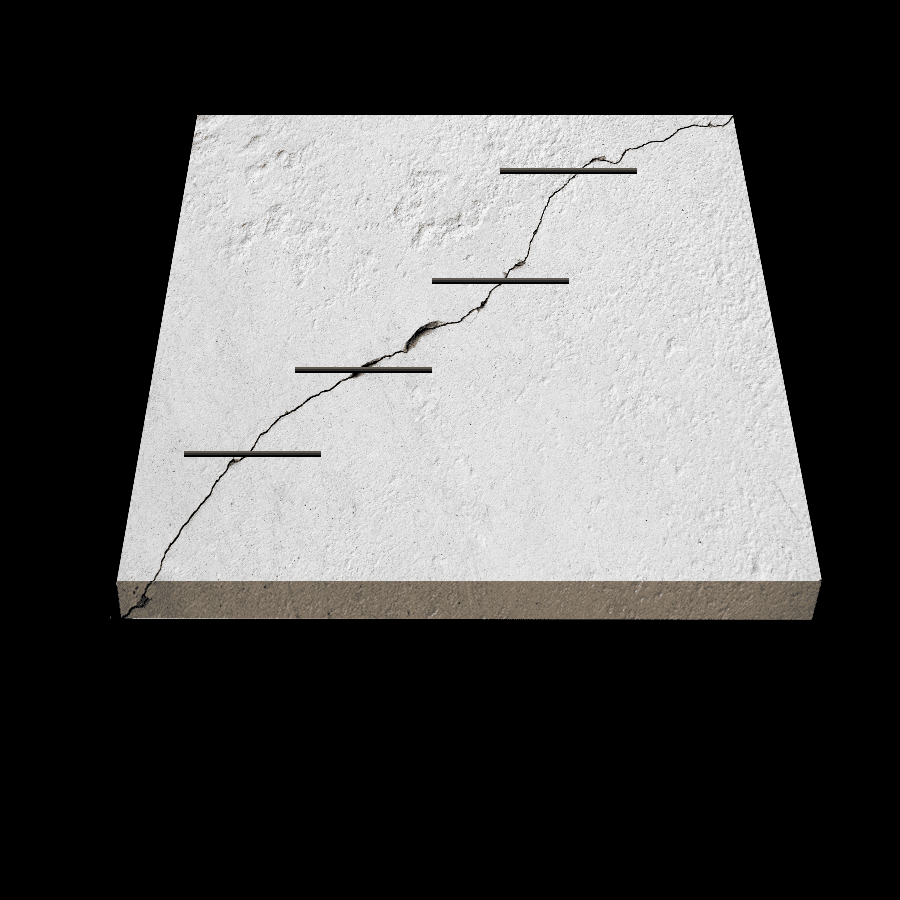

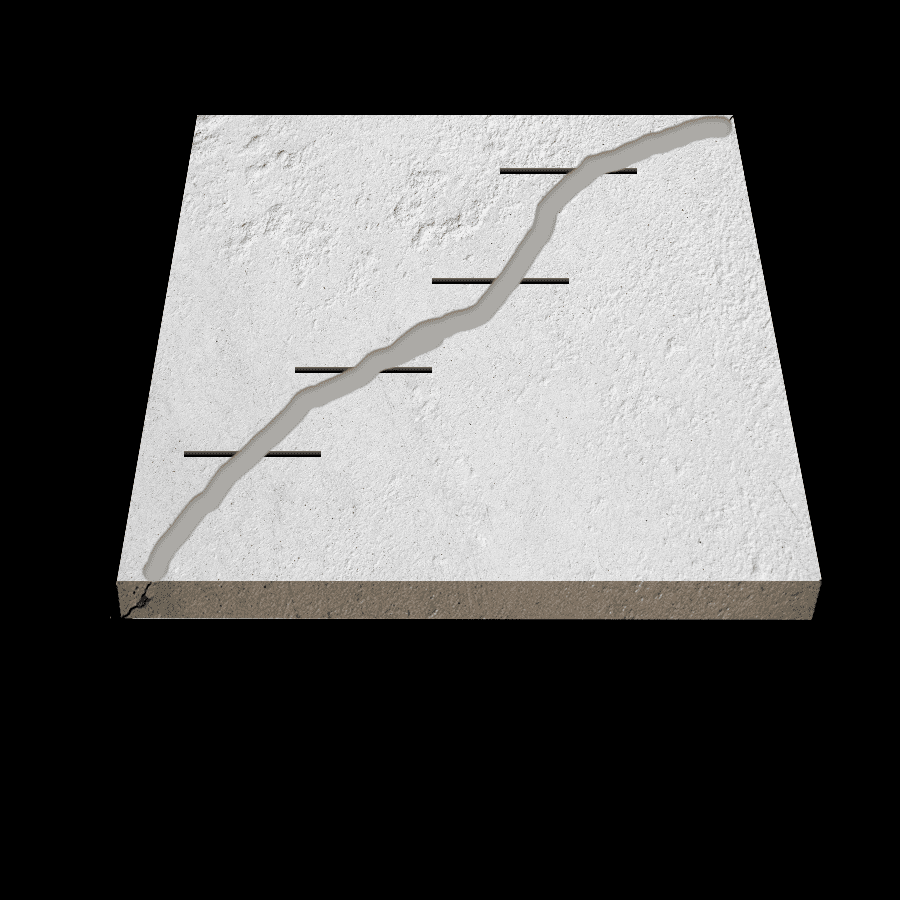

Soil Movement Can Cause Plaster and Pebble Finishes to Crack

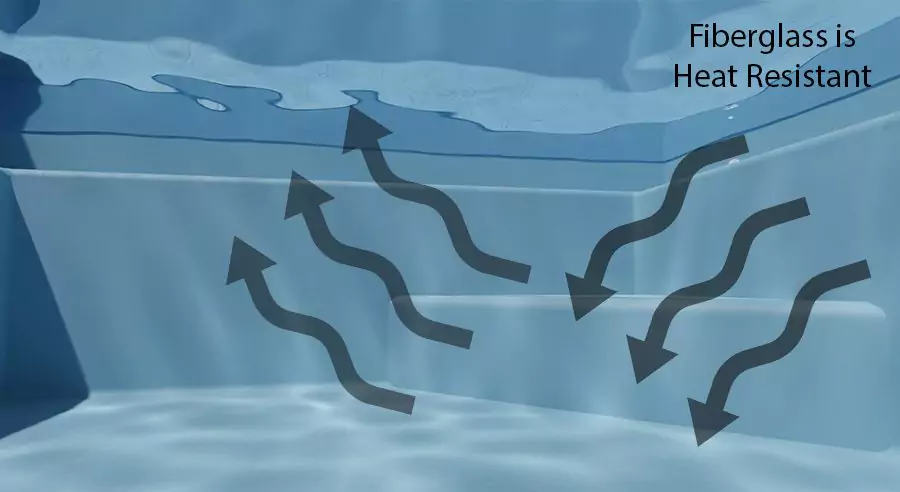

Fiberglass Resists Cracking

Why Not Paint?

We are not 100% certain as to why paint does not hold up in pools or spas or fountains.

We theorize paint is not a suitable resurfacing material due to the following reasons:

Paint applied to a fountain or pool surface may deteriorate due to constant water movement, harsh or standard chemicals used to maintain the water’s chemistry, sun or weather related damage, the fountain or pool surface being exposed to sunlight without water covering it, inconsistent water treatment or maintenance, abrasive brushes rubbed on the fountain or pool surface, poor workmanship when applying the paint product, poor quality paint product, or paint material and surface not being compatible.

While there are better paint based products compared to others – based on our experience the life span for most pool related paint products are extremely minimal for commercial or residential fountains or pools or spas.

Fiberglass Advantages

Durability: Fiberglass has greater durability than plaster or pebble surfaces

Heat Resistance: Especially important for commercial installations where water is heated 24/7

Algae Resistance: Making pool easier to maintain

Easy Maintenance: No floor brushing or water balancing required

Stain Resistant: Any surface stains are easier to remove than with plaster or pebble surfaces- Prevents Copper Staining

Cures Without Water: The fiberglass is already cured by the time water goes in

More Advantages

Smooth Surface

Composite fiberglass surfaces have a smoother feel than plaster. Due to the inert nature of fiberglass, no leachable/extractable material is available to cause roughness. The surface remains smooth.

Crack Prevention

Prevents most or all pool shell cracks from showing

Prevent water loss due to cracks

Color Options

Multiple color options are available.

PSI Protection

Fiberglass Has The Highest PSI protection out of all interior swimming pool or spa surface materials

Convenience

Once fully dry, pool can be filled and you are ready to swim. Compare this with a 30 day wait for plaster or mini pebble

Less Porous

Fiberglass is less porous than plaster, which contributes to easy maintenance.

Waterproofing

Composite waterproofs the entire swimming pool

Water Temperature

8 to 10 degrees warmer

Crack Repairs

When cracks are present in the swimming pool shell-composite is the only option.

Faster Installation

Lower Lifetime Cost

No liner replacement or resurfacing needed

Corrosion Resistance

Structural Strength

Superior tensile strength of composite material, ideal for pools with structural problems.

Algae Stains

Black algae cannot adhere to fiberglass. Rebar stains cannot bleed through.

Rust Stains

Resists rust stains from rebar

Copper Stains

Fiberglass resists staining from copper piping

Life Expectancy

Not subject to water or chemical corrosion. Longevity exceeds that of cement-based specialty/aggregate plasters

Long Term Aesthetics

Excellent water clarity and sparkling appearance. Superior aesthetics over the life of the surface.

Comfort

NO scratched feet or toes

Structural Cracks

Fiberglass adds structural strength to the pool shell and prevents leaking.

15 Year Warranty

The odds of fractures or deep cracks showing or becoming visible through your swimming pool interior surface is dramatically lowered. While we cannot guarantee cracks will not appear or show we can say we have never seen a crack reappear within our warranty time frame .

The very nature of composite materials implies that a more comprehensive, realistic warranty is offered.

Schedule Maintenance 1-2 Days After Pool is Full

Get ph to right level

Turn pump on

Ready to swim

Can start heating asap

Compare to plaster or mini pebble 30 days for mini pebble

Our Process

First Coat: A coat of resin is applied as a primer (Roll-On)

Second Coat: Resin Plus Fiberglass (Roll-On)

Third Coat: Resin is applied (Roll-On)

Foutth Coat: Gel Coat (Color is added in this step)

Fifth Coat: Final Coat (Sprayed On)

Our Process

First Coat

A coat of resin is applied as a primer (Roll-On)

Second Coat

Resin Plus Fiberglass (Roll-On)

Third Coat

Resin is applied (Roll-On)

Fourth Coat

Gel Coat (Color is Added in this step)

Fifth Coat

Final Coat (Sprayed On)

Fiberglass Application

Sprayed or Rolled

Lights and Drains

Pool Light and drains are installed after spray next day

Between Coats

Surface is sanded between each coat

Note:

Fiberglass should not be exposed to the sun past 2-4 days the fiberglass is dry

Drying

Need to wait for fiberglass to be 100% dry before putting water in the swimming pool

*Please note: warmer days like summer we wait 1 day

If it’s colder we wait 2-3 days

For all Fiberglass Jobs we Take the Following Steps:

1. Treat all Visibile Flaws and Cracks

2. Apply First Primer Coat of Isophalic Resin

3. Laminate Total Area with Fiberglass Mat and Resin

4. Apply Third Coat of Isophalic Resin

5. Apply the Final Coat of Gel

What is Gel Coat?

Uses

Gel coating, also known as gelcoat, is a type of surface coating commonly used on the interior surfaces of swimming pools, as well as on boats and other fiberglass-reinforced plastic (FRP) structures.

Benefits

It serves several purposes, including enhancing the appearance of the pool, protecting the underlying materials, and providing a smooth, water-resistant surface.

Our Novel Process For Crack Repair

What is Recommended

Expose Cracks

Install Staples Every 6 In

Use 6500 psi hydraulic cement

Coat with Fiberglass

Your one stop solution for Cracked or damaged swimming pool shells

Treat all visible flaws & cracks

Apply first primer coat of Isophalic resin

Laminate total area with fiberglass mat and resin

Apply third coat of Isophalic resin

Apply final coat of gel

Add composite behind waterline tiles if existing tiles are being replaced

We Intall Hydrostatic Valves

These special valves are used if the pool has been empty or if there are aggressive leaks present.

In addition, we place SDX covers over the hydrostatic valves we install.

Crack Repair

Expose Cracks

Install Staples Every 6 In

Use 6500 psi hydraulic cement

Coat with Fiberglass

Treat all visible flaws & cracks

Apply first primer coat of Isophalic resin

Laminate total area with fiberglass mat and resin

Apply third coat of Isophalic resin

Apply final coat of gel

Add composite behind waterline tiles if existing tiles are being replaced

Fiberglass Services

We fiberglass all common outside surfaces

Swimming pools

Vinyl pools or above ground pools or manufactured pools

Fountains

Remodeling

Spas

Planter Boxes

Anti-Slip Surfaces

Decks, Steps

Diving Boards

Steps For Ladders

Fiberglass Repair

Kevlar reinforced crack repair

Solutions for pools with structural tile problem

Rolling resin and fiberglass onto swimming pool and spa surface

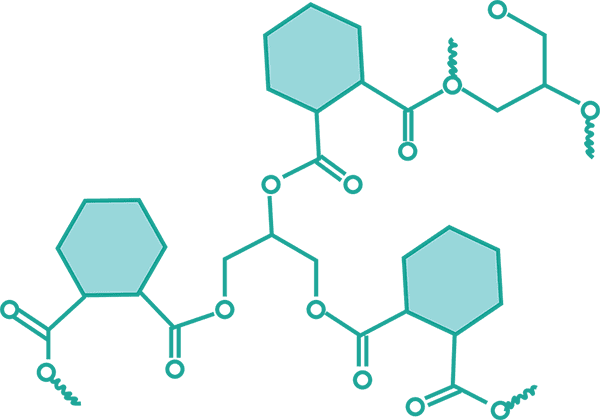

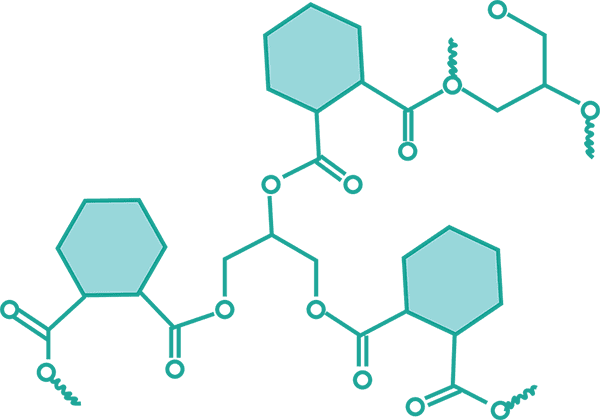

Glass Coat

Guarenteed to Outlast & Outperform Other Materials

Pigment integral glass/polymer matrix Glasscoat Layer 2

Fiberglass Eliminates

Cracks and Leaks

Algae and Staining

Rough Surfaces

Discoloration

High Chemical Usage

Rebar Stains

Plaster Problems

Pool Conditions |

Plaster |

Glass Coat |

|---|---|---|

ROUGH SURFACES |

As plaster wears, roughness increases. Quartz and pebble plaster becomes rough with age. |

Always smooth. No scratched feet. |

STRUCTURAL CRACKS |

Any substantial pool movement can cause cracks and leaks. |

Adds structural strength to pool shell. Prevents leaking |

BLEMISHES & STAINS |

Little resistance to stains and blemishes, even if surface has been recently applied. |

Resistance to stains, with easily cleaned surface. |

ALGAE RESISTANCE |

Algae adheres to porous surface. |

Smooth, dense, non-porous surface prevents algae from adhering. |

CHEMICAL DEMAND |

High chemical requirement at all times. Reactive surface. |

Noticeable reduction in chemical usage due to the inert nature of Glasscoat. Makes pool chemicals more efficient. |

APPEARANCE |

Unsightly when stained/ deteriorated. |

Maintains attractive appearance. |

DURABILITY |

Depends on application. Replaster often separates from original surface (poor adhesion). Material limitations reduce the durability of plaster. |

The superior corrosion resistant and inert properties of Glasscoat ensure exceptional durability. |

WATER CHEMISTRY |

Very sensitive to incorrect water chemistry. Plaster surface easily compromised. |

Inert surface less sensitive to out-of-balance water chemistry – a very forgiving surface. |

WARRANTY |

Because of material limitations, very limited warranty offered (workmanship only). |

Applied by specialists. More comprehensive warranty offered. |

LIFE EXPECTANCY |

Varies and depends on water chemistry, maintenance regime, plaster mix and application technique. Average is 5–7 years. |

Far exceeds service life of plaster. Time tested with 30 years industry experience. |

START-UP |

complicated. Requires brushing and attention. |

Simple. No brushing needed. Allow to cure, then start-up. |

Smooth Non-Porous Texture

Learn More

Simple, more cost effective startup; no brushing or tending needed

Commercial Fiberglass Pools

Fiberglass | Composite is ideal for commercial swimming pools, spas, and fountains or waterfalls.

No large trucks required to mix plaster or mini pebble materials

No blocked traffic or large barriers inconveniencing tenants

No long tubes which plaster requires

No impossible to reach areas no matter what floor or area the swimming pool or spa is located in

No large amounts of water required like plaster

Yes you can use the swimming pool immediately

Yes you can heat the swimming pool and spa immediately after the project is complete

Mobile – easy to apply on any floor of any sized sky scraper vs. plaster or mini pebble

FAQs

I have a fiberglass pool in need of repair, can you help me?

Absolutely! call us today to have someone come out and inspect the problem and tell you what can be done.

Visit the Contact Us page

How is fiberglass superior to any other surface?

It is well established that fiberglass is far superior to any other pool surface. Fiberglass lasts much longer than plaster or pebble surfaces, eliminating the need to resurface over and over through out the life of the pool. Fiberglass is smooth eliminating painful skin abrasions, and virtually non-porous making it virtually impossible for algae to get a foot-hold, unlike that of plaster or pebble surface. In addition fiberglass can save you 30% to 50% on chemicals.

What affect do chemicals have on fiberglass?

We use a premium highly corrosive resistant resin that can be used to make containers to store corrosive chemicals. However, chemicals such as pool acid and chlorine over time will attack and break down a plaster surface and pebble surfaces.

What if I have a vinyl liner pool?

Vinyl liner pools can rip, tear and fade and are subject to puncturing. A permanent easy solution to this is to have your pool fiber-glassed.

How long does fiberglass last?

Fiberglass comes with a limited-lifetime warranty from peeling, cracking or chipping of fiberglass.

How much does fiberglass cost?

Shop Swimming Pool Options

Equipment

Plumbing

Electric

Coping

Shotcrete

Recent Articles

The Lifespan Saver: The Importance of Timely Swimming Pool Plaster Repair

When it comes to your backyard oasis, the sparkling blue waters of your swimming pool are the core of relaxation and enjoyment. However, over time, wear and tear on the pool plaster can compromise both its aesthetic appeal and structural integrity. At CPR Pools LLC,...

Spillways and Spa Walls: Transforming Your Pool into a Stunning Retreat

Looking to transform your pool into a stunning retreat? Adding a spa spillway or spa wall can give your pool the upgrade it needs. Not only do these features enhance the overall aesthetics of your backyard oasis, but they also provide relaxation and tranquility for...

Pool Plumbing and Equipment- The Essential Guide for Your Pool or Spa

From Design to Reality: Pool Plumbing and Equipment in Construction Are you a homeowner in California with dreams of having your own swimming pool or spa? If so, it's important to understand the ins and outs of pool plumbing and equipment. From water jets to solar...

Contact Us

Request an appointment in person or by phone

call or text 818-792-5020

Contact Us

Call or text 818-792-5020